Undercarriage Vehicle Scanning Solution for Trains

TREX-UVSST

TREX-UVSST is an inspection solution that helps technical inspectors

to quickly and safely inspect the entire chassis and lower sides of wagons.

This solution uses the latest digital camera technology, LED lighting and Artificial Intelligence (AI) image processing algorithms.

When a train passes through a checkpoint, the solution :

- Captures high-resolution images of the chassis and side parts of each wagon.

- Automatically detects and identifies the position of certain sensitive parts : bogie, spring, buffer…

- Automatically recognizes each wagon’s registration number…

Thanks to the high-definition images produced and automatic detections, the solution helps operators to carry out a digital technical pre-inspection of each wagon. Then, the operator can visualize and trace areas showing anomalies, non-conformities, damage or wear, before carrying out an on-site inspection. This optimizes technical inspection time.

TREX-UVSST is the essential tool to support the wagon inspection and identification process at terminals or rail maintenance centers.

Inspect wagon chassis,

Detect any non-conforming parts,

And ensure the maintenance process.

The TREX-UVSST solution is designed to :

- Capture high-resolution images of the entire convoy undercarriage.

- Read wagons and containers codes (option).

- Automatically recognize characteristic parts of a wagon by AI.

- Automatically detect particular equipment, anomalies, wear points, part variations through stored reference images.

- Run specific analysis of the detected parts (contat us)

- Alert operator in case of any need of maintenance detected.

- Allow operator to efficiently and safely inspect the entire train at a railway, multimodal, maintenance or logistics terminal entrance.

- Archive all information collected during the passage of trains in an SQL database.

- Integrate with external systems : maintenance systems …

- Be efficient 24h/24.

- Withstand various climatic constraints, vibrations, etc.

- Offer a powerful Software Suite with a pleasant and intuitive graphic interface.

Benefits

Increases safety and security

thanks to high-resolution monitoring of train chassis images.

Easier maintenance

thanks to a precise view of the condition of the undercarriage and wagon sides.

Reduces human risks

on the track.

Traceability of railway convoy

by archiving all data acquired in a database.

Ease of integration

with third-party systems.

technical ChARACTeRISTIcs

EQuipment

- Inspection scanners : 1 central and 2 lateral (optional)

- Automatic cleaning system for central scanner (high-pressure blowers)

- Additional cameras and lighting on masts or gantries

- Electrical cabinet, sensors, cables and connectors

- Acquisition and processing PC

- TREX Software Suite from NESTOR TECHNOLOGIES

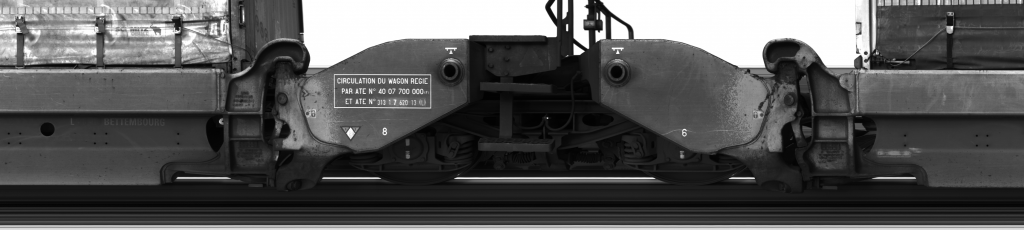

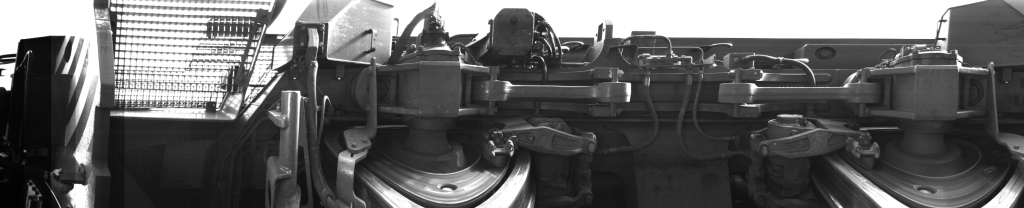

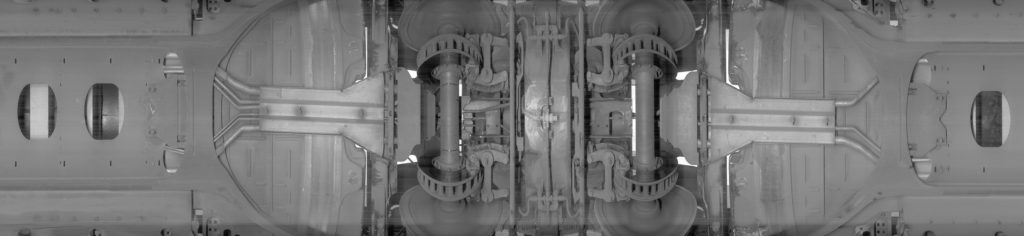

inspection images

High-resolution panoramic images for each car:

- Undercarriage (by a central scanner fixed between the tracks)

- Lower external sides (by 2 optional side scanners)

- Upper parts (by optional cameras mounted on masts or gantry)

The level of detail is in the millimetre range.

processing modules

- Automatic Wagon Number Recognition (AWNR)

- Automatic detection of characteristic wagon elements (ARCD) using Artificial Intelligence: bogie, spring, buffer, etc.

- Special parts on request (contact us)

optional modules

- Automatic Container Code Recognition (ACCR)

- Automatic recognition of ADR codes

- Analysis of detected elements: measurement, wear detection, etc. (contact us)

data

Export of all collected data (date, time, site, track, inspection images, wagon number, detected elements, container code, registration…) at checkpoints to an SQL database (PostgreSQL, Microsoft SQL Server…) via the TREX secure Web Service, or to XML files, or to any other system via a specific export plugin.

efficiency

The TREX-UVSST solution is fully automatic system, efficient 24 hours a day.

For optimum inspection, trains speeds of up to 20km/h are possible.

For higher speed, please contact us.

technical support

Technical support through remote control of the system.

main applications

Finally, the inspection of the chassis and lower parts of trains (cars + locomotives) is essential for :

- Terminals : multimodal, railway

- Railway maintenance or sorting sites

- Industrial sites that have their own access to railroads

- Check points or Border crossings

Other TREX Solutions :

TREX-CONTAINER

TREX-WAGON

TREX-UVSS